Heat treatment is often used in the

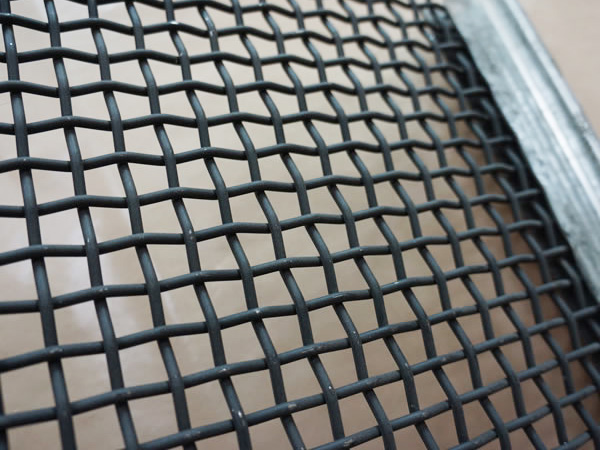

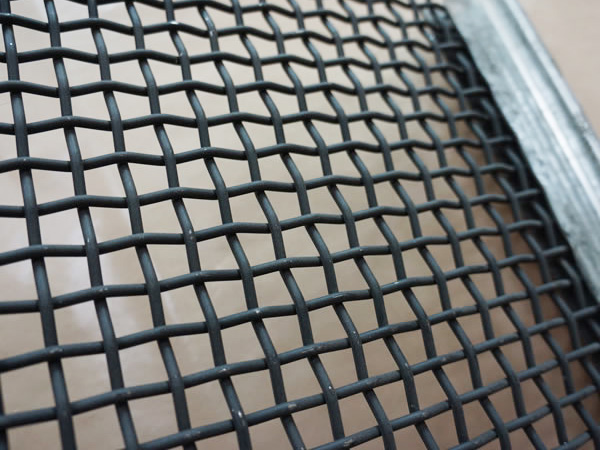

security mesh screen processing a processing skills, after heat treatment of security mesh screen more heat, high temperature. In the use of the use of more, so how is the heat treatment?

Heat treatment is to put the information in the medium must be heated, heat preservation, cooling, through the table data appearance or internal arrangement structure, to manipulate the function of an induction process. High-frequency current flows to the high-frequency machine is made Rao hot coil, thereby changing the instantaneous magnetic flux occurs in the coil, the metal, and other objects to be heated is placed in the coil, the magnetic flux will be heated throughout the object.

In the interior of the object to be heated and the heating current in the opposite direction, corresponding to a large eddy current occurs. Because the object is heated in the memory of the resistance, so many Joule heat will occur, the temperature of the object itself is a quick rise, to reach all the metal heating data intentions related content: stainless steel

security mesh screen processing sheet thickness is important?

Stainless steel

security mesh screen Anti-high temperature oxidation function at ambient temperature in the air is generally used at least 13 percent (component) increase in chromium and 26 percent for harsh environments. The Chromium passivation layer constitutes an oxide (Cr2O3) of chromium (III) exposed to oxygen. The layer is too thin to be visible and adheres to the shine and lubrication of the metal. The layer is impervious to water and air, maintaining the underlying metal, this layer quickly changes when the outer surface is scratched. This phenomenon is called passivation.