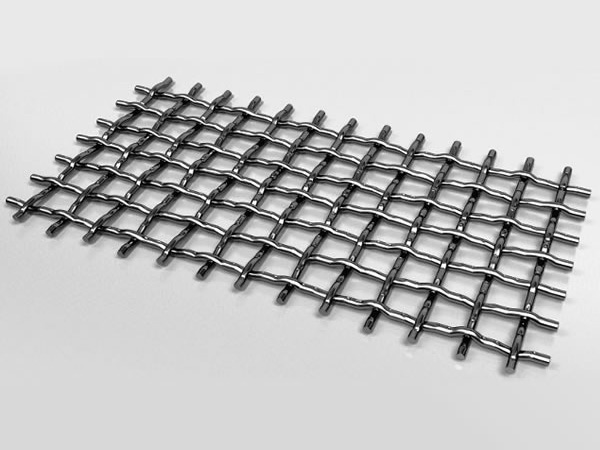

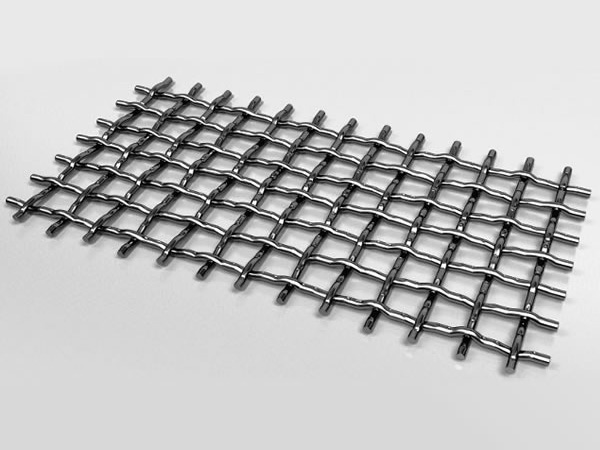

1, check whether the

Vibrating Screen Mesh latches in the same position on both sides of the screen box.

2, the use of Henan tensioning screen, check the eight hammer wedge block is clamped, the use of composite crochet screen, check the tensioning nut

The degree of tightness is consistent.

3, the box on the Strip and the plastic sheet are worn and damaged, if necessary, should be replaced.

4, check the screen is warped, if necessary, should be repaired or replaced.

5, Check the Vibrating Screen Mesh all nuts, bolts, washers are loose, especially on the motor and tighten the motor base plate nuts, bolts, washers

Reliable fastening (check once per shift), there cannot be the loose phenomenon.

6, two vibrating screens are best used interchangeably, to improve the bearing, screen and other parts of life is good.

7, stop screening, should be promptly washed with water screen, and with a brush to clean the screen online drilling and embedded in the mesh of sand.

8, in use. Drilling fluid paste phenomenon should be stopped in time to wash the screen.

9, monitor whether there is an abnormal sound, especially the sound of the collision between the bearing or metal if there should be stopped immediately.

10, every two months after working

Vibrating Screen Mesh (running 1400H) should be on the motor of each bearing lubrication once.