Excellent polyurethane screen products will always have a variety of counterfeit and shoddy, which makes users friends a headache, if you, unfortunately, buy a polyurethane screen with insufficient quality, there will be many problems, so for this problem, today we are looking for polyurethane screen manufacturers. The technical staff will introduce you to relevant knowledge and teach you several methods to identify the quality of the polyurethane screen. If you can keep in mind the main points, I believe that you can greatly improve your chances of purchasing high-quality products.

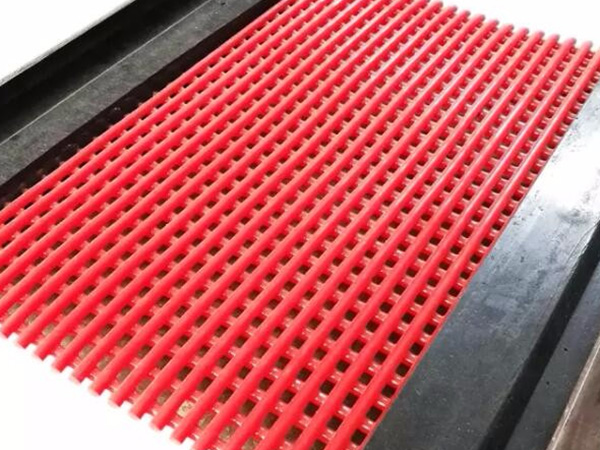

1. Look at the opening ratio of the polyurethane screen. The opening ratio is the most direct factor affecting the screening power. If the meshing number of the polyurethane sieve is larger, the higher the opening ratio, the higher the screening power and output.

2. The connection of the polyurethane screen is also an aspect that everyone must pay attention to.

The connection method of the polyurethane sieve will directly affect the power of the screening. The polyurethane screen arrives at a close connection with each other and does not leak minerals to ensure the grade.

3. Carefully observe the appearance, whether the surface of the polyurethane sieve is exquisite, whether the sieve is flat or not, and pay attention to whether the color of the polyurethane sieve is pure, whether there is a broken strip, burr, lack of material, mixing, tight seam and so on.

The polyurethane screen has an operating life of 8-10 times compared with the general metal screen, 3 times that of the stainless steel screen surface and 3.9 times that of the natural rubber. It is the best screen surface material in the world.

The production information of polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flex resistance, and load-bearing capacity.

The polyurethane screen's production materials have been specially treated to ensure that they will never delaminate under long-term alternating loads.